Inside a Natural Gas Compressor Station Spectra Energy

Inside a Natural Gas Compressor Station 8 4 6 5 7 1 Natural Gas Fuel Gas Lube Oil Muffler For more information, visit . Natural gas is pressurized as it travels through the interstate pipeline system. To ensure that the gas continues to flow optimally, it must be periodically compressed and pushed through pipelines.

What Is a Natural Gas Compressor Station? KB Delta

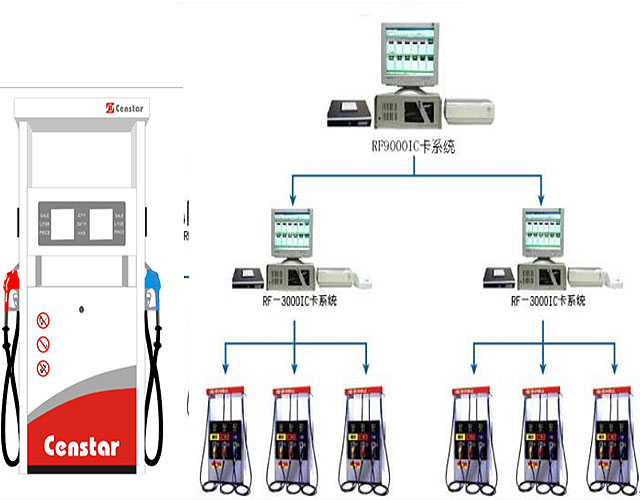

So, every forty or one hundred miles, a natural gas compressor station is placed to restore pressure to the gas. A natural gas compressor station contain several: Safety systems. Monitoring implementations. Backups to protect the complex as well as nearby neighborhoods. Some modern compressor stations are operated remotely, and are staffed only by a small crew or an as needed maintenance team.

Dangerous Neighbors: Pipelines, Compressor Stations, and

Natural gas pipelines and compressor stations are associated with specific risks and health problems, which frequently bring the most harm to low income communities and communities of color, often given little or no choice about hosting gas infrastructure in their communities.

Compressor Stations Construction and Maintenance

Compressor stations are outposts placed at various regular points along a natural gas pipeline that house the equipment needed to main the proper pressure gradient needed to ensure delivery. The primary component of any such station is the actual compressor unit.

Future Compressor Station Technologies and Applications

Small to midsized simple or combined cycle natural gas power plants located near a pipeline compressor station • Process: Use pipeline natural gas to support electrical power production to dependably drive an EMD compressor train as part of baseload • Potential: Overall process operational and reliability advantages over

Natural Gas Compressor Stations Explained Hanging H

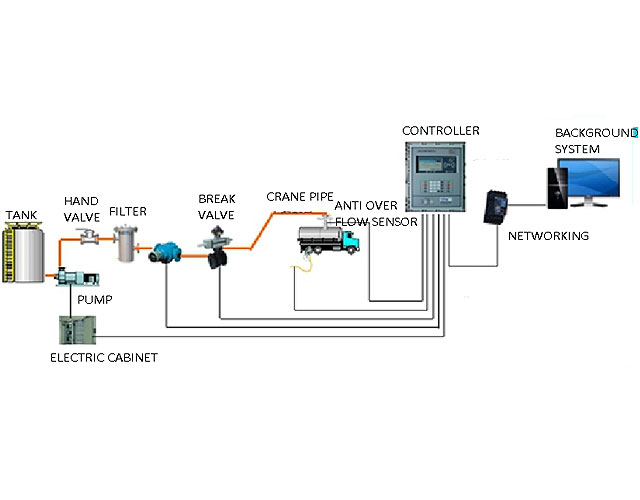

There are basically three stages for a natural gas compressor station: scrubbing, compressing, and cooling. The natural gas compressor station layout is fairly straightforward, as the gas compressor stations process is a continuous flow process. Here is a natural gas compressor station process flow diagram, courtesy of Spectra Energy.

Compressor Stations PG&E, Pacific Gas and Electric

Nearly 40 percent of our natural gas supply enters the system at our Topock Compressor Station, which is located 15 miles southeast of Needles, California. The next station is located in Hinkley in San Bernardino County.

Compressor Stations: What They Do, How They Work, and Why

Filters and Scrubbers As mentioned above another component of compressor stations are filters and scrubbers which remove water, hydrocarbons, and other impurities from the natural gas. Gas Cooling Systems When the natural gas is compressed its temperature rises. This is usually offset by having the gas travel through cooling systems which return it to temperatures that will not

Natural gas cooling for compressor station

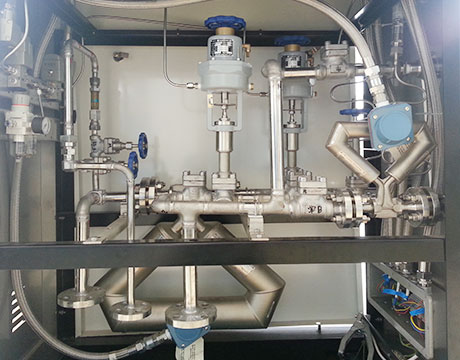

Natural gas cooling for compressor station Exploration and production company Location: Central U.S. Application: Natural gas cooling The challenge An exploration and production company needed three systems to cool high pressure natural gas in a multistage compression system

What Is a Natural Gas Compressor Station? KB Delta

So, every forty or one hundred miles, a natural gas compressor station is placed to restore pressure to the gas. A natural gas compressor station contain several: Safety systems. Monitoring implementations. Backups to protect the complex as well as nearby neighborhoods. Some modern compressor stations are operated remotely, and are staffed only by a small crew or an as needed

Midstream Oil and Gas: How A Gas Compressor Station Works

Gas cooling systems. Compressing natural gas causes its temperature to rise. Midstream companies often run the gas through gas cooling systems that lower the gas temperature in order to prevent pipeline damage. Compressor stations are typically located every 40

Natural Gas Compression Station Cooling, Natural Gas

Fog Provides Cooling for Natural Gas Pipeline Compressor Stations High pressure fog enables pipelines to maintain production levels and stay online during hot weather conditions. After new compressor units were installed at a North Carolina compression facility, the cooling systems began to reach capacity causing the compressor to overheat due to hot weather conditions.

Air Pollution Control Permits for Natural Gas Compressor

Compressor stations are used to pump natural gas through pipelines. Compressors, located at intervals along a pipeline, pressurize the gas to keep it moving through the pipeline. Most compressor stations sit on about an acre of land and run on diesel or natural gas fuel.

The basics of a compressor station The McIlvaine Company

Natural Gas Cooling System. Re pressurizing natural gas in the compressor results in an increase in the temperature of the gas. Gas coolers are used to cool the gas to 45 C in order to maintain the efficiency of the pipeline and protect internal coatings from undue wear.

Cooling Natural gas

Natural Gas Cooling. Absorption Systems Absorption cooling systems rely on a cycle of condensation and evaporation to produce cooling. The absorption process is driven by a heat source rather than a mechanical compressor, like those used in electric chillers. Absorption systems are available as chillers or chiller/heaters,

Engine Cooling System Upgrade At Natural Gas Compressor

In 2016, Bodine Electric completed work for a natural gas customer that provided an overhaul and upgrade of an engine cooling system. The work, at a natural gas compressor station, included: Installation of Eaton motor starters; Fan motor installation and alignment performed by Bodine’s electro mechanical repair division

Natural Gas Compressor station components AONG website

the gas compressor station consists of the following units: a suction scrubber. a gas manifold or a distribution header. gas compressor “single or multiples stages” according to the required discharge pressure. gas cooler fan. discharge scrubber. condensate gathering system. corrosion inhibitor skid. a dehydration unit. metering station.

How do natural gas compressor stations work? Socratic

Gas Cooling Systems When the natural gas is compressed its temperature rises. So for this the gas is made to travel through a cooling sector. Which cools down the temperature of the gas so the pipeline is not damaged through which the gas is travelling. Mufflers These are basically the Noise controllers of the Compressor Stations.

Message

Message tel

tel Inquiry

Inquiry