Why differential pressure gauges? Flow Control Network

Differential pressure in liquid level. Again, like flowmeters, there are many types of level gauges. A simple, relatively inexpensive solution is to use a differential pressure gauge to indicate the level of a liquid within a tank. In open tanks, the high pressure side of a DP gauge is ported to the bottom of a tank,

Why Differential Pressure Gauges? Orange Research

Differential Pressure in Liquid Level. In open tanks, the high pressure side of a DP gauge is ported to the bottom of a tank while the low pressure side is mated to atmosphere. In this scenario the DP gauge is measuring a column of liquid within the tank, resulting in a reading that reflects the height of the liquid within the tank,

Different Types of Pressure Gauges Synonym

Pressure gauges measure the increase and reduction of pressure in a contained field. The earliest patent for a tube pressure gauge was issued to France's Eugene Bourdon in 1849. Still in use in the twenty first century, the popular Bourdon pressure gauge measures different kinds of liquids and gases including steam, water and air.

Pressure measurement Wikipedia

Pressure measurement. A vacuum gauge is a pressure gauge used to measure pressures lower than the ambient atmospheric pressure, which is set as the zero point, in negative values (e.g.: −15 psig or −760 mmHg equals total vacuum). Most gauges measure pressure relative to atmospheric pressure as the zero point,

Externally Mounted Pressure Transducers for Tank Level

Gauge and differential pressure transducers can be installed externally to a tank for liquid or gas level measurement. Gauge and differential pressure transmitters are reliable, cost effective instruments to measure the hydrostatic level of liquids, such as water or fuel, in vented or sealed tanks.

Types of Pressure Gauges And Their Need in Industries

Pressure gauges are instruments used for measuring all types of vacuum and pressure operations. They accurately monitor the pressure being exerted in any operation. In short they are defined as instruments used to measure the pressure and force of a given gas or liquid.

8 Causes Of Pressure Gauge Failure Chemical Processing

The simple pressure gauge is an often overlooked defense mechanism for preventing accidents. However, in auditing more than 250 plants, WIKA Instrument discovered that up to 25% of all pressure gauges were broken, damaged or misapplied — this represents an average of eight deficient gauges located within 20 feet of each employee.

Pump Pressure Tanks, how they work and how to set them.

A pressure tank can be installed anywhere after this check valve. This means that when all the taps in the system are shut, then the pressure in the system builds. When the water pressure in the system builds to beyond the air pressure sored in the tank, then the air starts to compress and the water fills up the wet side of the tank.

How to Replace a Well Pump Pressure Gauge eHow

Well pump pressure gauges is a useful tool in monitoring a properly functioning water system. The ability to see at a glance the pressure of the well pump system can aid in any water flow problems. The pressure gauge is normally mounted on the pressure tank just above the well water pump pressure control switch.

Aquarium Storage Tank RO Storage & PSI Gauges

Aquarium Storage Tank, Drinking Water Pressure Tanks & PSI Gauge Products Drinking Water Pressure Tanks & PSI Aquarium Gauges. This is commonly called an RO aquarium storage tank. It is a bladder tank. Hydroneumatic, bladder, captive air, reverse osmosis RO storage & pressure tank are all common names for these tanks.

Different Types of Pressure Gauge mech4study

The pressure of the liquid easily measured by height of the liquid rise in the tube using scale attached to it. Piezometer is used to measure gauge pressure only because surface of liquid is in contact with atmospheric pressure. The drawback of piezometer is, it can’t be used to measure very high pressure and gas pressure because one end is open.

5 Techniques For Pressure Gauge Adjustment and Repair

Some pressure gauges have an adjustable knob in the lower side of the body. This is a diaphragm type pressure gauge that is usually used in water treatment pipings. Just remove the lock then the knob will freely turn to adjust the needle. 4. Adjusting the screw located inside the pressure gauge mechanism

Differential Pressure Gauge Applications Differential

Consequently, a differential pressure gauge must be used by connecting the high side to the bottom of the tank and the low side to the top of the tank. As a result, tanks measuring liquid oxygen, nitrogen, argon, and much more can have a cost effective solution to getting an inside look at their liquid levels.

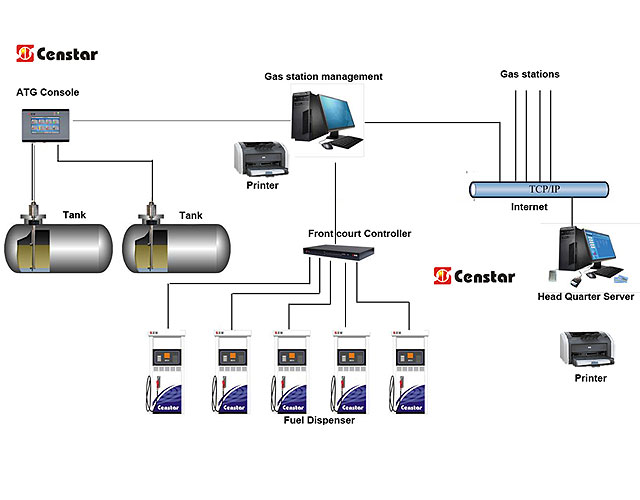

How to Check and Adjust Pressure Tanks Censtar

If you are on a private water system you probably have a pressure tank. It is important to check it every so often to ensure the system is functioning properly. The video will show you how to

Engineering Essentials: Pressure Gauges & Flow Meters

However, to obtain a reasonable fatigue life and motion that is more linear with pressure, a coil spring supplements the inherent spring rate of the bellows. These spring loaded bellows gauges generally are used in pressure ranges having spans to 100 psi and to 1 in. Hg. Metallic diaphragms also are used as the elastic chamber in low pressure gauges.

Anesthesia Machine Flashcards Quizlet

the pressure reduction valve takes the pressure inside the tank (2000 psi) and reduces it to what psi? flow meter mechanism that allows anesthetist to set gas flow rate (amount of O2 in L/min) that travels through the machine and delivered to the patient

list of pressure measuring devices Pressure Transducers

Stain gauge pressure transducer is used for narrow pressure span and for differential pressure measurement. Conclusion : Hope you find your list of the pressure measurement devices. Here we show which transducers are used for pressure measurement. Here we saw a different pressure gauge for measuring mechanical pressure.

Why Does The Air Compressor Have Two Gauges?

In short, the regulator is used to reduce the available tank pressure to the best operating pressure of the air tool or air using equipment. As you turn the knob on the air regulator, the pressure display on the regulator air gauge will change too and indicate the pressure setting that the downstream air will receive.

Troubleshooting a bladder pressure tank

Check the tank’s pressure by placing an air pressure gauge on the air charging valve on the top of the tank. Add air if the pressure is more than 2 psi below the pump cut in pressure. Use caution when using an air compressor or air pump. Release air if the pressure is 2 psi above the pump cut in pressure (lowest pressure in the operating range).

Parts of a Pressure Gauge Hunker

Gear Mechanism. Each gear in a pressure gauge gear mechanism is precision built in order to move the pointer accurately. The required ANSI accuracy rating for a particular pressure gauge ultimately determines how the gear mechanism is designed. Pressure gauges that read finer increments of pressure require more complex gear mechanisms.

Message

Message tel

tel Inquiry

Inquiry