UNDERGROUND STORAGE TANK INSPECTION CHECKLIST

B. System Maintenance and Operation 1. Remove product from sumps, dispenser pans 2. Find and repair leak(s) 3. Provide required cathodic protection system inspection/documentation 4. Provide required inspections for lined tanks 5. Secure monitoring wells 6. Repair monitoring system 7.

Septic Inspection Checklists & Worksheets

Septic System Inspection & Testing Field Inspection Data Worksheets Detailed Guidance for Septic system testing, diagnosis, pumping, repair design, defects, alternatives, inspection methods Defects in onsite waste disposal systems, septic tank problems, septic drainfield problems, checklists of system components and things to system maintenance and pumping schedules.

Sample Forms & Checklists For HVAC Installation Testing

Sample Forms & Checklists For HVAC Installation Testing & Commissioning In: Method Statements , Testing & Commissioning Tagged: blank performa , blank proforma , HVAC Forms , inspection checklist , installation checklist , sample check list , sample checksheet , testing formats

Maintenance Checklist Convault

Water in the tank will cause increased corrosion. If you discover water in the primary tank it must be removed. One method is to pump it out with a “Thief Pump”, a small pump that pulls the water from the bottom 1/8” of the tank. Check tank openings for possible water entry points.

Release Detection for Underground Storage Tanks (USTs

View EPA's publication, Automatic Tank Gauging Systems for Release Detection: Reference Manual for Underground Storage Tank Inspectors, for information on evaluating how well UST owners and operators are using their ATG systems to comply with release detection requirements.

NCDEQ Forms

UST Installation Inspection Checklist: 12/2009 : UST 10B: UST General Requirements Inspection Checklist: 7/2010 : UST 12: Closure Report Format: 8/2008 : UST 13: Compartment Tank Notification: 2/2001 : UST 15: Change of Ownership of UST System(s) 10/2015 : UST 15A: Ownership of UST Systems: 10/2015 : UST 16: Manual Tank Gauging Record: 10/2015

Forms and Applications

Storage Tank System Closure Report for underground tanks is comprised by the following documents: Planning for Permanent Closure Checklist (2630 FM BECB0126) (Word and PDF). Checklist for planning permanent closure. Notification of Release Notification of Contamination Form (2630 FM BECB0082) is available in Word and PDF formats. Notification form for releases and suspected or confirmed

Operating and Maintaining UST Systems

An automatic tank gauging (ATG) system consists of a probe permanently installed in a tank and wired to a monitor to provide information on product level and temperature. ATG systems automatically calculate the changes in product volume that can indicate a leaking tank. Perform These O&M Actions

A Roadmap for Installing and Commissioning New

Equipment: Water tank, birdcage, SunNuclear Edge S/N, electrometer S/N Setup: Align robot vertically at 75 cm SSD (use fixed cone front pointer!). Mount diode on birdcage. Verify diode is centered and parallel to surface. Data Analysis: Use provided by vendor.

Plumbing Inspection Checklist RESULT OF INSPECTION

Plumbing Inspection Checklist Cayman Islands Government Department of Planning P.O. Box 113, Grand Cayman KY1 9000 Check water pressure with a gauge 312.5 8. Drainage and vent air test 312.3 that piping is properly supported 308.1 tank shall have not less than two tanks 802.3 18. Inspect system for leaks

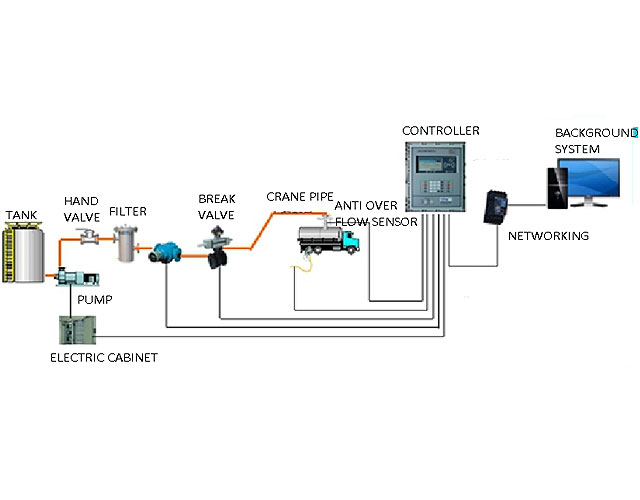

Tank Gauging System Spartan Controls

Raptor is a state of the art inventory and custody transfer radar tank level gauging system. It is developed for a wide range of applications at refineries, tank farms and fuel depots, and fulfills the highest requirements on performance and safety. The field devices on the tank communicate over the intrinsically safe Tankbus.

Industry Offshore Marine Technava

SURVEYOR™ systems are designed, developed and manufactured in Norway to the highest standards and in full compliance with the gov erning class and IMO regulations. SURVEYOR™systemsmeetthedemandforlowcostandtimesaving installation, with minimum expenses for maintenance during their

CCTV System Installation Checklist

CCTV System Installation Checklist Analogue and IP CCTV Systems Infinique CCTV Systems Installation Checklist w w w . i n f i n i q u e . c o m DS VS IOM 201412V01 1 Project Details Checklist Date Client Name Checklist Filled by Contractor Name System Integrator Analogue System IP System Video Analytics

TANK MANAGEMENT MANUAL

Registration of regulated tanks must be performed within 30 days of installation or new ownership of the tank system. A regulated substance may not be placed in the tank and the tank may not be operated until it is properly registered and PADEP issues a certificate that serves as an operating permit for the tank.

Enraf Microlect Tank Gauging System OSIsoft

This document describes the Enraf Tank Gauging System Interface (PI Enraf) to the Plant Information (PI) System. The Interface runs on Windows NT 4.0. It communicates with the Enraf Tank Gauging System via a local RS232 port connected to a communications port on a Microlect System. The protocol is described in detail in the Enraf document:

Investigative Checklists for Waste TCEQ

Criteria used by TCEQ investigators during site visits. Made available to the public as a courtesy so those investigated (routinely or due to a complaint) can know what the agency will look for.

MONTHLY BULK DIESEL ABOVEGROUND TANK

MONTHLY BULK DIESEL ABOVEGROUND TANK INSPECTION CHECKLIST Tank: _____ Inspector Name: _____ Signature: _____ Date: _____ YES NO*N/A 1. Is the tank system free of visual signs of damage (cracks, dents, corrosion or leakage): a. Tank exterior including small cracks in concrete exterior or rusting on steel components? b.

DO IT YOURSELF SEPTIC INSPECTION CHECKLIST: Pressurized

PUMP TANK QUESTIONS (pages 19 20 in the field guide) Is the riser water tight and free of cracks and damage? o. Yes . o. No . o. Not Present Is the pump tank free of solids? o. 337 127 DIY Do It Yourself Septic System Inspection Checklist on site onsite sewage wastewater inspect

Septic Inspection Checklists & Worksheets

Field worksheets for various types of septic system inspections can be found at Checklists for Inspecting, Testing, & Maintaining Residential Septic Systems. See Septic Tank Inspection Procedure for details of inspecting septic tanks themselves and a septic tank inspection checklist.

Message

Message tel

tel Inquiry

Inquiry