Dip Stick vs. Automatic Tank Gauge Accuracy Home EMS

Dip Stick. The process of manually dipping tanks correctly can take up to 30 minutes each day. In addition, the practice usually calls for weekly water paste tests per tank, which, when conducted correctly, will add another 30 minutes per week.

Level Measurement Process Control Instrumentation Training

Servo Operated Level Gauge on a Spherical Tank. This simple level measurement has a dip tube installed with the open end closeto the bottom of the process vessel.A flow of gas, The over all level should be equal to or higher than the upper (low pressure)tap 4. There is always a reference level seen by the low pressure side.

Hydropneumatic Tank Control Systems

of the tank or installed separately. The liquid level switch senses the water level with an electrode suspended inside the tank. The pressure switch senses the air pressure in the tank. Both sensors are set to maintain the desired water level inside the pressure tank by controlling when the air compressor runs. As air dissolves into the water, the

The Art of Tank Gauging ICEWeb

However, if the level is under P2 there is no differential pressure measurement. This will be the case when the level is only 1.5 m to 2.5 m (6 ft to 8 ft) above the tank bottom. With many tanks, the density in the heel of the tank will be different from the density at higher levels.

A Dozen Ways to Measure Fluid Level and How They Work

Other level detection devices include those based on specific gravity, the physical property most commonly used to sense the level surface. A simple float having a specific gravity between those of the process fluid and the headspace vapor will float at

Automatic Tank Gauging (ATG) North Dakota

Components of an Automatic Tank Gauging System. An ATG uses probes located in each tank or compartment to measure fuel and water levels. Each probe consists of a long rod with floats or sensors. The position of the floats tells the ATG console how much fuel and water are present in the tank.

A dozen ways to measure fluid level and how they work

A dozen ways to measure fluid level . The demands of sophisticated automated processing systems, the need for ever tighter process control, and an increasingly stringent regulatory environment drive process engineers to seek more precise and reliable level measurement systems.

Automatic Tank Gauging Products Veeder Root

The TLS4i / TLS4c Automatic Tank Gauge for Small Retail and Commercial Applications. The Veeder Root® TLS4i/TLS4c Automatic Tank Gauges (ATG) are affordable wet stock management solutions that deliver accurate and crucial information. The TLS4i and TLS4c ATGs are a great way for retail, aviation, or bulk fueling customers who may be using

The disadvantages of manual dipping Gilbarco Veeder Root

The disadvantages of manual dipping. Dipping with paste does not reliably detect water in the tank. Water allows the proliferation of microbial growth in diesel tanks (B2 onwards) that impacts flow rates at the pump and eventually damages the dispenser. One of the many benefits of the Automatic Tank Gauging system is automatic water detection,

Fuel Tank Gauging Systems & Dip Rods, Sticks Tank Gauging

Dip Sticks. Accurately calibrated dip rods are manufactured at our head office using tank data supplied by the tank manufacturer or customer as the original durable and easy to read dip sticks are the yard stick which can be used in the event of tank gauging problems or discrepancies.

Automated Calculations for Improvement of Tank Inventory

The purpose of tank gauging is to determine the physical quantity of petroleum products contained in a storage tank. A high degree of accuracy is required since the volumes will be used to quantify a custody transfer movement and consequently money will change hands based on the results.

Storage tanks basic training (rev 2) SlideShare

The construction of the gauge poles depends on the operational conditions and the required measurement accuracy of the level Dip plate or datum plate A 6 mm thick dip plate shall be provided for welding to the tank bottom or lowest shell course directly under the dip fittings (i.e. dip hatch, slot dipping devices and combined vent

Gauge or Dipstick — Rigging Doctor

The combination of checking your tanks with a dipstick before setting off and then monitoring with gauge readings is the best compromise for evaluating fuel levels. Dipsticks are valuable instruments to verify the amount of fuel stored within a tank and should not be completely replaced by an electronic gauge.

What is Automatic Tank Gauge? Definition from Petropedia

Automatic tank gauge (ATG) systems measure the levels of liquids inside tanks with the help of electronic probes. These probes consist of long rods that house certain number of sensors known as floats. The position of the floats informs the operator sitting at the ATG console about the amount of petroleum product present in the tank.

Common Tank Gauging Technologies and How They Work Varec

Varec’s float and tape tank gauge solution consists of a 2500 ATG selected for the appropriate tank type. The instrument provides a measurement to +/ 4 mm accuracy and tank side display that is suitable for inventory management to API specifications.

Dip Chart Tank Gauging Systems Corp

Tank Gauging Systems Corp Global Liquid Level Monitoring & Burner Management Oil and Gas. Edmonton (780) 474 2365. Tank Gauge Dip Chart VERTICAL TANK. Enter Height. Enter Diameter. Input. Inches Tank Chart Values:

Manual Tank Gauging for Small Underground Storage Tanks

Manual tank gauging can be used only on tanks 2,000 gallons or smaller. Tanks 1,000 gallons or smaller can use this method alone. Tanks from 1,001 to 2,000 gallons can use manual tank gauging only when it is combined with periodic tank tightness testing. The combined method of manual tank gauging and tank

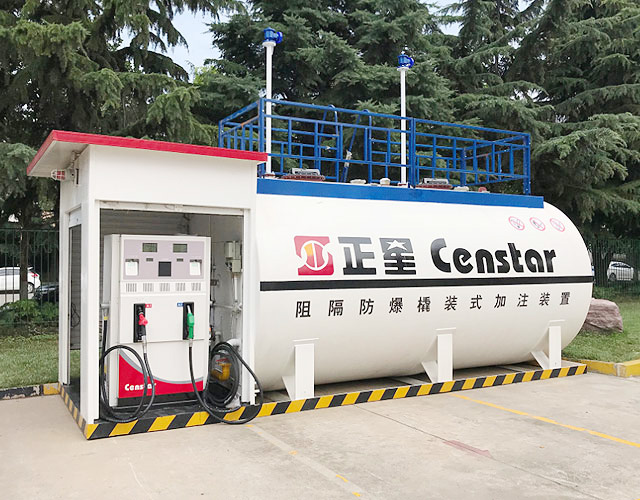

How to dip a fuel tank Censtar

PowerPoint presentation on measuring the amount of heating oil in an underground tank. Skip navigation How to dip a fuel tank Karen Simmons How To Install Level Gauge Manual Float

7 Setting Up Tanks and Flow Meters Oracle

Set up additional tank information after setting up basic tank information. Tank Strapping Table Maintenance: W415003B: On Tank Master Maintenance, after setting up basic tank information, click Cancel to return to Work With Tank Master. Select the tank you set up and select Tank Strapping from the Row menu. Set up tank strapping information.

How To Make A Dipstick For A Storage Tank Censtar

"dipstick for storage tank", "oil tank dipstick", "tank measurement stick", "dip rod" "fuel dipstick"

Message

Message tel

tel Inquiry

Inquiry