CSMF50 (50000L)

Censtar was set up in 1992. Censtar has been keeping the No.1 in fueling dispenser industry, with around 40% market share in domestic market. Now, a huge sales and service network spread all over the nation to support the customers.

CSMF10 (10000L)

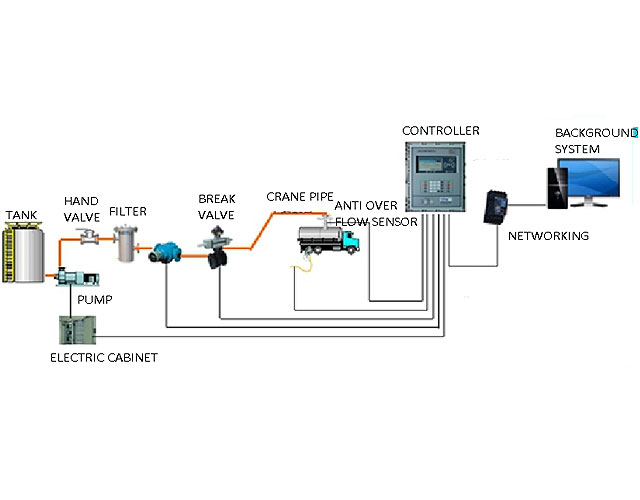

And the automatic alarm & control system can find abnormal condition in time and carry out emergency treatment. Energy saving and emission reduction The device is equipped with vapor recovery system that can restrain and reduce oils volatilization as well as reduce pollution to atmosphere environment.

Gilbarco Nozzle Stainless Steel Breakaway Connector For

Gilbarco nozzle stainless steel breakaway connector for vapor recovery system. Self sealing break away valve,which connects vapor recovery nozzle and coax ial hose,is to protect fuel dispenser,hose sets and vehicles by it ’ s quick disconnection and shut off of the oil circuit

Installing Vapor Recovery Units on Storage Tanks

vapor recovery units (VRUs) on storage tanks. VRUs are relatively simple systems that can capture about 95 percent of the Btu rich vapors for sale or for use onsite as fuel. Currently, between 7,000 and 9,000 VRUs are installed in the oil production sector, with an average of four tanks connected to each VRU.

Control emissions. Recover valuable hydrocarbons. A range

vapors to the loading or storage operation. Vapor recovery systems significantly reduce the loss of profitable products with recovery efficiencies up to 99% plus and recovery rates between 1 to 2 liters per 1,000 liters loaded. In many applications, return on investment can occur within a few short years. A range of systems to meet any application.

ZEECO PRODUCTS & INDUSTRIES Vapor Control Vapor Recovery

ZEECO® Vapor Recovery Systems. Wherever fuels are loaded into trucks, ships or rail cars, VOCs can escape into the atmosphere and create both harmful and unacceptable emissions levels. Zeeco offers the industry's most advanced vapor recovery systems (VRUs) to match your precise application to ensure maximum capture of hydrocarbon vapors.

Control of Vapor Recovery Units (VRU)

Diversity of vapor recovery processes Vapor Recovery Systems are based on different processing principles. Processes use adsorption, absorption, conden sation and membrane separation principles to recover hydrocarbons from vapors and to clean the exhaust gas stream to a level that complies with emission limits. Activated Carbon Adsorption

Gas Compression and Vapor Recovery Systems Aereon

Carbon Bed Vapor Recovery Unit (VRU) Hundreds of customers around the world rely on AEREON liquid ring and dry vacuum based VRU systems that economically recover a variety of VOCs in truck, rail, marine storage and loading applications. AEREON also provides comprehensive service support for carbon VRUs, including other manufacturers’ brands.

Oil & Gas Vapor Recovery Systems PetroGas Systems

Vapor Recovery Systems Suppliers ThomasNet

Vapor Recovery Systems are compression systems that capture and compress vapors from chemical streams to prevent toxic emissions from being released into the atmosphere; thereby preventing air pollution and explosions. Typical applications include gas stations, refineries, food and beverage

fuel dispenser spare parts vapour recovery pumps

Fully interchangeable with all existing vapour couplings; The non return valve also allows emergency repair or servicing of the vapour coupler without loss of vapour <

Gilbarco Nozzle Stainless Steel Breakaway Connector For

Gilbarco nozzle stainless steel breakaway connector for vapor recovery system. Self sealing break away valve,which connects vapor recovery nozzle and coax ial hose,is to protect fuel dispenser,hose sets and vehicles by it ’ s quick disconnection and shut off of the oil circuit when the sudden leave happened.

Vapour recovery system VARECO Plus Double

The intelligent vapour recovery system VARECO Plus (Stage II) with the vortex flow sensor works completely automatic, self regulating and self monitoring, independent of temperature, pressure and density. It continually controls and regulates the vapour flow during the fuelling process.

vapor recovery system

Vapor Recovery Vacuum Pump JH Series Vapor Recovery Vacuum Pump is a relatively consummate pump for oil gasrecovery,working under the ambient temperature at 40~60℃,it can be used separately or as a part of oil gas recovery system in gas station,which is mainly used for oil gas recovery,to reduce pollution and save energy.

vapor recovery Equipment in Argentina Environmental XPRT

Join our growing community of environmental professionals who are currently subscribed to weekly newsletters, product alerts, job alerts, and our monthly event updates and article newsletters. Stay up to date with the global environmental industry. Sign up for one or all of our free newsletters and

Stage II Vapor Recovery Equipment OPW Retail Fueling

OPW offers several varieties of Stage II Vapor Recovery Systems, including the centralized Micro VacuRite OPW offers solutions for conventional, vapor recovery, DEF, Ethanol, Biodiesel, CNG, LPG and Hydrogen fueling, as well as a complete portfolio of solutions for above ground storage tanks.

US6131621A Vapor recovery system for a fuel dispenser

A vapor recovery system for use in a fuel dispenser. The system has a vapor recovery line for collecting fuel vapor. A Fleisch tube is mounted in the recovery line and connected to a differential pressure transducer for monitoring the volumetric flow rate of fuel vapor through the recovery line. The Fleisch tube provides highly accurate flow rate measurements which are used to set the

Helium Gas Reclaim/Recovery Systems ThomasNet

Helium Gas Reclaim/Recovery Systems manufacturers, service companies and distributors are listed in this trusted and comprehensive vertical portal. The comprehensive directory provides access to full contact and ability information for sourcing professionals, engineers and researchers wishing to get information on Helium Gas Reclaim/Recovery Systems.

ETNYRE Tank Trailers For Sale 22 Listings TruckPaper

Central America. Belize ETNYRE Tank Trailers For Sale . 22 Results Found This Page: 1 of 1. Units: Imperial (US) Type; Yes Vapor Recovery; 2015 Entyre 8500 Gallon Crude Oil Tanker with 5000 Gallon Pup AIR RIDE CENTRIFUGE PUMP VAPOR RECOVERY SKULLY SYSTEM For Sale Price: USD $185,000. Purchase today for USD $3, /monthly*

Fuel dispenser Wikipedia

Higher flow rates may overload the vapor recovery system in vehicles equipped with enhanced evaporative emissions controls (required since 1996 in the US), causing excess vapor emissions, and may present a safety hazard.

Vapor Recovery Monitor (VRM)

Enhanced Vapor Recovery (EVR) Phase II System and how to properly troubleshoot these systems. For complete installation, operation, and maintenance details of this system, refer to CARB Executive Order VR 202. An ISD system is comprised of one vapor pressure sensor per site, one vapor flow meter per dispenser, one tank gauge

suction dispenser suppliers and suction dispenser

Dispenser Mounted Vapor Recovery Pump. Model / Specifications:HSP02 Individual Type. Brand Name:Censtar. Theory:Vacuum Pump. Details: Dispenser Mounted Vapor Recovery Pump Features1) Powered by a suction dispenser pump motor, no additional motor.2) Special material for piston ass

Gasoline Vapor Recovery (Stages I and II) TCEQ www

Stage II Vapor Recovery System Enforcement Discretion Directive. GDFs currently equipped with Stage II systems must continue to comply with existing Stage II requirements in 30 TAC Part 1, Chapter 115, Subchapter C, Division 4 . Also, GDFs that meet the requirements of this directive must continue to comply with the Stage I requirements in 30 TAC

Message

Message tel

tel Inquiry

Inquiry